CSCLT

Cold Spring

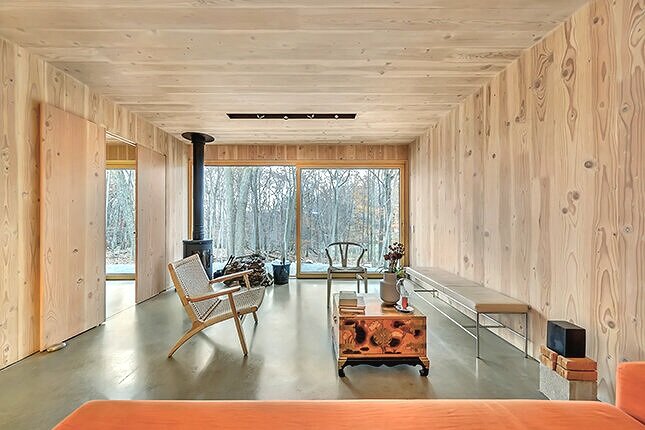

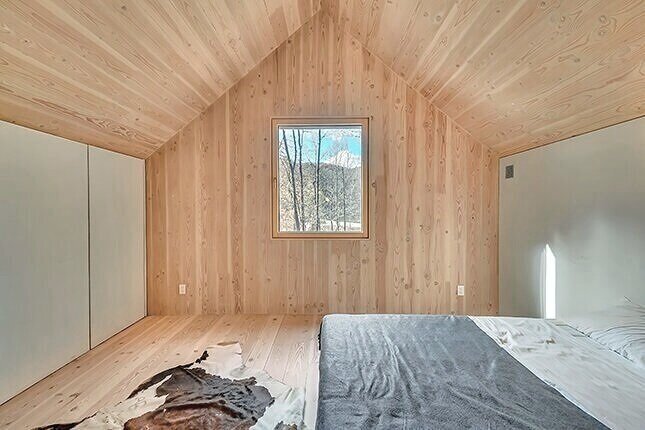

This project is the first Cross Laminated Timber residential project in NY State. The experimental construction-efficient and low-energy house design utilized 42 CLT panels, replacing the thousands of components of traditional 2x or masonry construction. The CNC machined parts reduced field errors and minimized the number of joints forming an extremely well built and air tight structure erected in 10 working days. Furthermore, the structure is wrapped with Gutex, a wood fiber exterior insulation widely used in Germany. The new insulation and CLT panels in conjunction with all-wood windows, natural cedar wood shingles, and stained cedar wood siding contribute to an extremely wood-intensive project. The CLT panels were left exposed at the interior where ever possible to illustrate this and to reduce additional and any unnecessary finishes.

The project investigated the reduction of on-site work, economization of component and factory-made parts, the detailing of exposed CLT interiors and its integration with building infrastructure (wiring, piping, ducting, etc.). The project achieved comparable costs/sf as conventional construction in the Hudson Valley area. Monitoring equipment is currently recording energy-use to determine the actual overall performance of the design.

The triple glazed windows (with tilt-turn and lift-and-slide functionality), wood stoves, and high-efficiency ducted split-system with heat pump and wifi enabled controls update the traditional all-wood house into a modern day low-energy consumption home that meets Passivhaus standards and details.